| FAQ | Member List | Albums | Today's Posts | Search  |

| Welcome Guest. ( logon | register ) | |||||

| ||||||

|

|

| Topic Tools  | Message Format  |

| Author |

| ||

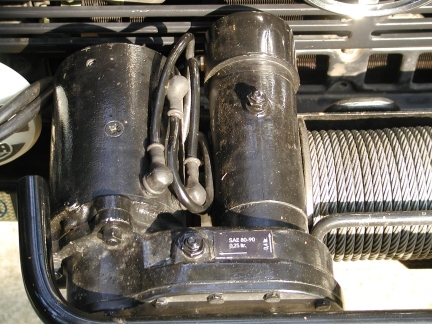

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | Rotzler rebuild Since my 1984 280GE originally came with a Rotzler winch, I always thought it would be nice to have one fitted again. Through Guido from OffRoadWorld I was able to have a good deal on such a winch, although it needs some work to make it nice and running again. I thought it would be nice to show some pics of it and show the (probably slow) progress to have it 100% again. I've started a search for additional info, parts lists and wiring diagrams and with the help from Rotzler and other forummembers I'm sure to have enough technical info handy for all the rebuild. For now, some questions I have: - I thought the Rotzler winch type for the G-class was ER 1500 (that's also listed on the typeplate I have on my G), but the type plate on the winch says it's EZ 015 / 909370-0001. Year of built is 1988. EDIT: through Hipines scans on http://autos.groups.yahoo.com/group/usgwagen/files/Rotzler%20Winch%... I learned that ER 1500 is similar to EZ 015... - Did anybody dismantle the electrical control box? It was damaged and rusty and the electrical connectors were not that nice, so I tried to disassemble it. After removing the steel box, I found the whole control box is some big epoxy block. Are all components poured in this epoxy? If so, I would need a new control box or build some control box myself. See also the last picture. gr. Bram Edited by bram_r 3/7/2010 12:29 PM (1.jpg) (2.jpg) (3.jpg) (4.jpg) Attachments ----------------  1.jpg (93KB - 8 downloads) 1.jpg (93KB - 8 downloads) 2.jpg (96KB - 7 downloads) 2.jpg (96KB - 7 downloads) 3.jpg (118KB - 7 downloads) 3.jpg (118KB - 7 downloads) 4.jpg (77KB - 7 downloads) 4.jpg (77KB - 7 downloads) | ||

| #167768 |

| ||

| Author |

| ||

| DUTCH Administrator Doppelgänger Date registered: Apr 2006 Location: US, GA, Atlanta Vehicle(s): 2015 Audi Q7 3.0 TDI,2018 Sprinter Posts: 9963  | RE: Rotzler rebuild There are also a few photos of the Rotzler here: http://www.pbase.com/flydutch/gwagen_rotzler_winch | ||

| #167770 - in reply to #167768 |

| ||

| Author |

| ||

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | RE: Rotzler rebuild DUTCH - 3/7/2010 6:53 PM There are also a few photos of the Rotzler here: http://www.pbase.com/flydutch/gwagen_rotzler_winch thanks Dutch, but I already looked at your site many many times! however I can now focus a bit more on specific details. bram | ||

| #167774 - in reply to #167770 |

| ||

| Author |

| ||

| G4Garret Veteran Date registered: Apr 2006 Location: Oak Ridge - Knoxville - Windrock Tennessee Vehicle(s): 2000 G500, U1100, SLK350, LR 101, WC-63 6x6 Posts: 243  | RE: Rotzler rebuild I don't know if this helps any or not, and maybe you already know, but that winch in Dutch's pictures appears to be identical to a Ramsey winch, at least as far as the motor, controls, reduction box and worm drive are concerned. It is just mounted inverted from what is normal, with the drain plug and breather's reversed. And when I say identical, I mean even some of the casting and machining marks on the housing appear the same. I have a very similar winch (Ramsey DC-200) on my Military Land Rover, and I also had to rebuild the control box, which as I recall, was easy to do. Although that was probably 1985 and everything was easier back then So I suppose you have options. You could rebuild it yourself like I did mine with a custom home-brew design, or you could by a factory solenoid assembly from a company like Ramsey, or you could find an original Rotlzer. If you want to build it yourself, I can take some pictures of mine for you. Garret | ||

| #167777 - in reply to #167768 |

| ||

| Author |

| ||

| G4Garret Veteran Date registered: Apr 2006 Location: Oak Ridge - Knoxville - Windrock Tennessee Vehicle(s): 2000 G500, U1100, SLK350, LR 101, WC-63 6x6 Posts: 243  | RE: Rotzler rebuild To see a basic schematic diagram and explanation of how the solenoids, motor, hand controller, and battery wiring work, you can look at page 25 of this pdf document: http://www.ramseypdfs.com/owners_search_pdfs/912407-0106-W.pdf | ||

| #167779 - in reply to #167768 |

| ||

| Author |

| ||

hipine Date registered: Jul 2006 Location: US, CO, Bailey Vehicle(s): 460 1980 280GE w. 617A  | RE: Rotzler rebuild Thanks for the great link! I've never had my Rotzler (the one off Dutch's old truck, actually) apart. It would be interesting to see if the spur gear box is as similar on the inside as it looks on the outside - meaning that brake setup. Interesting too to see Bram's potted solenoid box. I'm not sure how that works. The solenoids themselves need to move, and be cooled, so potting the whole mess seems a little strange. But I have to admit, it does seem to result in mine ALWAYS working when I plug it in and use it. Most of the winches with open solenoids end up needing the solenoid box re-loacated to a more protected place as they get full of crud travelling around on the bumper and don't work when needed. Hmmm. Intersting stuff. Thanks for chiming in! -Dave G. | ||

| #167808 - in reply to #167779 |

| ||

| Author |

| ||

| G4Garret Veteran Date registered: Apr 2006 Location: Oak Ridge - Knoxville - Windrock Tennessee Vehicle(s): 2000 G500, U1100, SLK350, LR 101, WC-63 6x6 Posts: 243  | RE: Rotzler rebuild I finally went out and took some pictures of my Land Rover's Ramsey winch, and the Rotlzer pictured in Dutch's photos sure looks like the Ramsey motor, worm and reduction assembly. This leads me to believe that if it is not made by Ramsey, then it's a licensed copy. Here is a pic from the underside of mine. I couldn't get the camera far enough away to get the whole assembly in the picture. Keeping in mind that the Rotzler is smounted inverted from normal, so the drain, breather and motor terminals are reversed.  And here is the Rotzler  And the Ramsey from the top side. You can see my home-made solenoid box on the left.   Edited by G4Garret 3/19/2010 11:03 PM | ||

| #168269 - in reply to #167768 |

| ||

| Author |

| ||

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | Re: Rotzler rebuild thanks man! Already the controller looks the same. I'm trying to find a Rotzler of Ramsey dealer here and see what I can find to purchase some missing parts. First I'll ask for some quotes on these parts, if they're not longer available or crazy expensive, I can build my own controller box. gr. Bram | ||

| #168294 - in reply to #167768 |

| ||

| Author |

| ||

hipine Date registered: Jul 2006 Location: US, CO, Bailey Vehicle(s): 460 1980 280GE w. 617A  | RE: Rotzler rebuild That is interesting. I agree, too close to be just by coincidence. Neither company's website mentions anything about the other, but it wouldn't be unusual for a company the size of Rotzler to fill out portions of its lineup with re-badged goods from quality suppliers. It would be interresting to send your observations to someone at Ramsey with some history with the company and see if they made winches for Rotzler at one time. It doesn't seem likely to go the other way around because of the huge diversity of things Rotzler produces. Much more likely that they found a good supplier for the light truck winch and re-badged it than for Ramsey to be making a living on one type of winch they buy/license from Rotzler. But you never know what's really behind the similarity unless you go to the horse's mouth. Would be fun to know. Thanks for sharing! Now you've got me wanting to go pull out that Rotzler documentation again and see if there are traces of its origin. -Dave G. Edited by hipine 3/20/2010 1:18 PM | ||

| #168296 - in reply to #168269 |

| ||

| Author |

| ||

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | Re: Rotzler rebuild I got some quotes from Rotzler now. It's really that they can supply still anything for their +25 yr old winches, but prices were pretty hefty to say the least... I guess I have to do some building myself when it comes to the motor controls and hand-controller. Bram | ||

| #168487 - in reply to #167768 |

| ||

| Author |

| ||

| nugat Elite Veteran Date registered: Jan 2007 Location: Warsaw, Poland Vehicle(s): 280GE, 290GD, c303 Posts: 876  | Re: Rotzler rebuild Bram, I have rotzler and the original electric switches just fell apart. I installed warn and they work fine both in wired and wireless versions. | ||

| #168612 - in reply to #168487 |

| ||

| Author |

| ||

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | Re: Rotzler rebuild that's nice to know, does the Warn controller box also have three wires going to the winch motor? bram | ||

| #168614 - in reply to #167768 |

| ||

| Author |

| ||

| nugat Elite Veteran Date registered: Jan 2007 Location: Warsaw, Poland Vehicle(s): 280GE, 290GD, c303 Posts: 876  | Re: Rotzler rebuild bram_r - 3/25/2010 9:15 PM that's nice to know, does the Warn controller box also have three wires going to the winch motor? bram Here the rotzler with warn control box. (P1010627.jpg) (P1010628.jpg) Attachments ----------------  P1010627.jpg (80KB - 8 downloads) P1010627.jpg (80KB - 8 downloads) P1010628.jpg (72KB - 6 downloads) P1010628.jpg (72KB - 6 downloads) | ||

| #168646 - in reply to #168614 |

| ||

| Author |

| ||

| G wizz Elite Veteran Date registered: Apr 2006 Location: Uk Vehicle(s): Dont own a G anymore, Too expensive!!!! Posts: 686  | Re: Rotzler rebuild I really don't know why you guys mount those control boxes in such a vunerable place, use sealed ones like that off albright, mount under bonnet with switch in cab Please ! | ||

| #168647 - in reply to #167768 |

| ||

| Author |

| ||

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | RE: Rotzler rebuild I've sourced some good control relais and hand controllers for a fraction of the cost of the Rotzler components. I'll rebuild a similar control box as Rotzler and mount it in the same location, so it will look stock. Just have to see which hand controller I use. I'd like to use a Rotzler one, but again, it's crazy expensive. One question about the Rotzler overload control. See the attachment. Outlined in red is nr. 53, a micro switch. Apparently, when the load on the winch becomes to big, the worm-shaft will shift a little (against a spring loaded bearing?) and the switch is actuated. But what happens when the switch is actuated? Does the complete winch stop working, or only winding the winch and unwinding is still possible? I don't see this safety feature in the Ramsey documentation. And with some proper winch use (ie. not abusing it) I don't think it's 100% necessary, but I'd like to know it's background. I also included a picture of the Rotzler control box; as it couldn't be repaired as it seemed, I decided to try to see how it was made up. Indeed, after 'slicing' it with a saw, it became apparent that the solenoids and wires are complete cast into this epoxy. As Dave earlier mentioned, I had my concernes about heat dissipation, but the picture shows how it is. Water resistent it'll be! Bram Edited by bram_r 3/28/2010 9:54 AM (31.jpg) (IMG_1286k.JPG) Attachments ----------------  31.jpg (115KB - 6 downloads) 31.jpg (115KB - 6 downloads) IMG_1286k.JPG (34KB - 6 downloads) IMG_1286k.JPG (34KB - 6 downloads) | ||

| #168720 - in reply to #167768 |

| ||

| Author |

| ||

hipine Date registered: Jul 2006 Location: US, CO, Bailey Vehicle(s): 460 1980 280GE w. 617A  | RE: Rotzler rebuild Interesting pix Bram. If I were in your spot I'd consider making the box on the winch a "dummy" and relocating the solenoids to someplace better protected from the environment. The Rotzler setup is very reliable genearlly due to its being sealed up. The solenoid packs from the likes of Warn and the rest seem to be destined to corrode and be unusable when needed, especially when hauled around on the front bumper in a northern european environement. Just a thought. Just remembered I forgot to get t-case pix. I'll remember one of these days. Too late now. -Dave G. | ||

| #168802 - in reply to #168720 |

| ||

| Author |

| ||

| elevatorbernie Expert Date registered: Aug 2006 Location: Vancouver B.C. Canada Vehicle(s): 1989 280GE Posts: 1347  | RE: Rotzler rebuild Bram, you could make a copy of the original solenoid block. Measure the old block, build a mold of same size from wood, then insert the new components pre-wired and then pour in some type of epoxy. The solenoid would have to be first sealed at every openning to keep the epoxy out. Edited by elevatorbernie 3/29/2010 12:36 AM | ||

| #168809 - in reply to #168720 |

| ||

| Author |

| ||

| Bushbenz Regular Date registered: Oct 2006 Location: Melbourne Australia Vehicle(s): 300GD Posts: 68  | RE: Rotzler rebuild Here is a circuit of the warn winch, and maybe yours is the same as most electric motors work the same way. The field coil is like a magnet (ie an electromagnet) and by changing the polarity it controls the direction of the motor. The armature coil is what turns and in this case is connected to ground. Looking at the pictures there appears to be 3 connections to your winch If you have a multimeter, set to ohm's and try to find the Armature coil that is the coil that is connected to the case of the winch. Put one probe of the meter on the case and touch then touch each of the 3 terminals successively, hopefully you will get a reading on only one terminal ( it should measure ~1 ohm). Then measure between the other 2 terminals you should get a similar reading, if this is the case then this is the field. This would mean its the same as a Warn and you can use a warn relay box. If this is correct and you now want to test the winch with some jumper leads connect the positive lead to one of the field coils, make a jumper lead (another jumper lead or wire something up) and connect the other field terminal to the armature terminal, then quickly tap the negative lead to the case of the winch, and it should turn. If you need to reverse the direction connect the 2 field connections the other way around. Steve Attachments ----------------  Warn circuit.pdf (78KB - 14 downloads) Warn circuit.pdf (78KB - 14 downloads) | ||

| #168974 - in reply to #167768 |

| ||

| Author |

| ||

| bram_r Expert Date registered: Apr 2007 Location: the Netherlands Vehicle(s): 1984 MB 280GE, 1982 MB 300GD, 1986 Subaru XT 4WD Posts: 1659  | RE: Rotzler rebuild elevatorbernie - 3/29/2010 6:26 AM Bram, you could make a copy of the original solenoid block. Measure the old block, build a mold of same size from wood, then insert the new components pre-wired and then pour in some type of epoxy. The solenoid would have to be first sealed at every openning to keep the epoxy out. I could do that, but apart from these sourcing these solenoids and wiring everything up, I think I go for an albright relais I see advertised at nice prices. Everything pre-wired in one waterproof housing, up to 480 amps, these relais are available around E 75,-. I will still install it of course in a housing that is about as large as the original Rotzler box. Also with a plug for the controller. I like these aluminum waterproof boxes I used to use for CAT machines, if I needed to install a custom option (see picture). The lid got a seal in it. Bram Edited by bram_r 4/3/2010 11:09 AM (albright.jpg) (rose housing.jpg) Attachments ----------------  albright.jpg (48KB - 5 downloads) albright.jpg (48KB - 5 downloads) rose housing.jpg (17KB - 5 downloads) rose housing.jpg (17KB - 5 downloads) | ||

| #169164 - in reply to #168809 |

| ||

| Author |

| ||

| elevatorbernie Expert Date registered: Aug 2006 Location: Vancouver B.C. Canada Vehicle(s): 1989 280GE Posts: 1347  | RE: Rotzler rebuild bram_r - 4/3/2010 7:35 AM That relay looks like alot less work and it would be servicable too, good choice. elevatorbernie - 3/29/2010 6:26 AM Bram, you could make a copy of the original solenoid block. Measure the old block, build a mold of same size from wood, then insert the new components pre-wired and then pour in some type of epoxy. The solenoid would have to be first sealed at every openning to keep the epoxy out. I could do that, but apart from these sourcing these solenoids and wiring everything up, I think I go for an albright relais I see advertised at nice prices. Everything pre-wired in one waterproof housing, up to 480 amps, these relais are available around E 75,-. I will still install it of course in a housing that is about as large as the original Rotzler box. Also with a plug for the controller. I like these aluminum waterproof boxes I used to use for CAT machines, if I needed to install a custom option (see picture). The lid got a seal in it. Bram | ||

| #169187 - in reply to #169164 |

| ||

| « View previous thread :: View next thread » |

|

|